| CRICKET

BATS ARE MADE OF WILLOW. IT IS TO BE

EXPECTED THAT THE CONDITION OF THE BAT

WILL DETERIORATE DURING ITS USAGE. THE

MANUFACTURERS HAVE PUT TOGETHER THE

FOLLOWING NOTES TO ASSIST THE EXPLANATION

OF SITUATIONS WHICH MAY OCCUR WITHIN THE

LIFESPAN OF ANY CRICKET BAT. |

BREAKAGE

1. HANDLE BREAKS

CAUSE - General wear and tear

SOLUTION - The bat itself is not

replaceable, but the handle may be

repaired at the MANUFACTURERS discretion. |

|

2.

BREAKAGE TO THE BLADE

CAUSE - Weak or excessively dry willow.

SOLUTION - Potentially replaceable by full

or partial credit, at MANUFACTUERS'

discretion |

|

BLADE

DAMAGE

1. SURFACE CRACKING TO THE FACE OF THE

BLADE

CAUSE - General wear and tear

SOLUTION - NOT REPLACEABLE, crack will not

affect the performance of the bat.

Repairable at the MANUFACTURER'S

discretion. |

|

2.

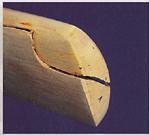

SURFACE CRACKING TO THE EDGE OF THE BLADE

CAUSE - General wear and tear

SOLUTION - NOT REPLACEABLE, crack will not

affect the performance of the BAT.

Repairable at the MANUFACTUER'S discretion |

|

3.

SURFACE CRACKING TO THE TOE OF THE BLADE

CAUSE - general wear and tear. This type

of damage is often caused by the striking

of a "yorker" delivery and/or

excessive tapping of the crease.

SOLUTION - NOT REPLACEABLE, crack will not

affect the performance of the BAT.

Repairable at the MANUFACTURER'S

discretion. |

|

4.

SPLIT THROUGH THE TOE AREA OF THE BLADE

CAUSE - This type of damage is caused by

the striking of a ball at, or near the

base of the blade, e.g. the driving of a

"yorker"

SOLUTION - Repairable and/or replaceable

at the MANUFACTURER'S discretion |

|

5.

CRACKING TO THE SHOULDER OF THE BLADE

CAUSE - General wear and tear

SOLUTION - NOT REPLACEABLE, repairable at

the MANUFACTURER'S discretion. |

|

6.

DAMAGE DUE TO MISUSE OF THE BAT OR BY

ACCIDENT

CAUSE - Generally caused by accidentally

striking an object other than the ball,

for example the stumps.

SOLUTION - NOT REPLACEABLE, may be

repairable at the CUSTOMER'S expense.

|

|

MOISTURE

DAMAGE

CAUSE - this type of damage occurs as a

result of use in damp or wet conditions.

It generally leads to swelling of the toe

area of the blade, which after drying may

well split.

SOLUTION - NOT REPLACEABLE, there is no

fault in the manufacturing or the

materials used. The damage may be

repairable at the MANUFACTURER'S

discretion and the CUSTOMER' S cost.

|

|

DAMAGE

DUE TO THE USE OF POOR QUALITY CRICKET

BALLS

Poor quality or excessively hard cricket

balls can be a cause of many types of

crack damage to the blade of the bat, as

previously illustrated.

ALL CRICKET BAT MANUFACTURERS recommend

that only balls of reputable manufacture

are used. Use of any other style or type

of ball may cause damage to bats and WILL

affect any claim made.

|

|

GENERAL

INFORMATION

1. CRICKET BAT WILLOW - English

willow (Salix Caerulea or Alba Var) is by

nature a soft fibrous reed. Performance

and durability are enhanced by drying and

pressing. In normal usage willow will

become bruised, scarred or dented simply

due to the nature of the game (the impact

with the ball.) The performance of the bat

will not be affected. Such marking can

occur at any time during the lifespan of

the bat.

2. KASHMIR WILLOW - Willow grown

overseas is by its very nature much harder

than English willow. Therefore bats made

of this type of willow will not have a

comparable level of performance with

English willow bats.

3. RETURNS - All repairs or

discounts given on replacement bats are at

the discretion of the MANUFACTURER. Bats

returned under complaint MUST be

accompanied by proof of purchase

(including date of purchase). Failure to

comply may affect the customer's statutory

rights.

4. LIFESPAN OF A CRICKET BAT -

There can be no definitive length of time

that a cricket bat will last. The

condition of a bat deteriorates with use.

The length of time before the player needs

to replace his bat will depend upon:

a) The amount of use

b) The weight of the bat (heavier blades

tend to be more durable than lighter ones)

c) The care with which the bat is treated

5. AGE OF THE CRICKET BAT - Bats

over TWELVE months old (from the date of

purchase) will be considered entirely at

the manufacturer's discretion, taking into

account the age and condition of the bat.

It is possible for the condition of the

bat to deteriorate even without use

(simply due to the natural drying out

process).

6. IN CASE OF DAMAGE - Immediate

action should be taken. This normally

necessitates withdrawal from play whilst

repairs are carried out. It is vital the

repairs are carried out by professional

bat makers. The manufacturers are unable

to guarantee repair work carried out by

non-approved repairers.

7. STORAGE - To ensure that a vat

remains in good condition it is essential

that it is not stored in excessively warm

conditions (e.g. near to central heating).

This will cause the bat to dry out and

precipitate future problems. The bat

should ideally be stored in a position

that will allow a little of the moisture

from the atmosphere to be absorbed.

PREPARATION FOR PLAY

The CRICKET BAT MANUFACTURERS recommend

the following principles for the

preparation and maintenance of cricket

bats.

Following these procedures will

significantly reduce the possibility of

damage occurring.

OILING

All natural faced bats MUST be treated

using raw linseed or a specialist cricket

bat oil. The main purpose of oiling is to

maintain moisture levels within the blade,

and hence reduce the chances of cracking

and splitting.

Light coats should be applied to the face,

edge, toe and back of the blade, taking

care to avoid the logos and splice area.

Generally two or three coats should be

sufficient. Each coat should be allowed to

dry into the blade, which should be kept

in a horizontal position before the next

is applied.

WARNING - DO NOT OVER OIL

DO NOT STAND THE BAT IN OIL

DO NOT LEAVE THE BAT IN A VERTICAL

POSITION AFTER OILING

BATS WITH FULL PROTECTIVE COATINGS SHOULD

NOT HAVE OIL APPLIED, BUT THEY MUST BE

CONDITIONED AS DETAILED BELOW

ALTERNATIVELY - It is possible to

fit a clear Anti-scuff or similar cover.

This does not negate the requirement to

"knock-in" the bat. The cover

may assist the durability of the bat, but

under no circumstances will it totally

prevent surface damage.

KNOCKING-IN

All bats are pressed, however,

"knocking-in" is VITAL. This is

the process by which the fibres of the

willow in the face and edges are

compressed together to form a barrier that

protects the bat against the impact of the

ball. Effective "knocking-in"

will significantly improve the performance

and increase the lifespan of the bat.

STAGE ONE

The "knocking-in" process should

be undertaken carefully using a special

bat mallet or an old quality cricket ball.

The bat should be repeatedly struck (with

gradually increasing force) in all areas

where one would normally expect to hit the

ball. This conditioning must be performed

with patience. Particular attention should

be given to the edges, although the edges

or toe should not be struck directly at

right angles to the blade. This would be

likely to cause damage.

This stage should take in the region of

six hours, although it may vary, as every

bat is different.

STAGE TWO

The next step is to graduate to the use of

the bat to hit short catches with an old

quality cricket ball. However, if the seam

marks the blade it is necessary to return

to "stage one" for further

conditioning. This stage should be

performed for at least another hour.

Once these steps have been taken, the bat

should be ready for use in matches. It is

advisable to initially avoid use against

the "new ball".

In addition to these steps it is

recommended that the purchaser follows

closely the "bat care"

instructions issued by the manufacturer.

WARNING

UNDER NO CIRCUMSTANCES SHOULD A BAT BE

USED IN MATCH CONDITIONS LESS THAN TWO

WEEKS FOLLOWING THE DATE OF PURCHASE. |